Browse Challenging Surface: Why Picking the Right Undercarriage Parts Issues

Browse Challenging Surface: Why Picking the Right Undercarriage Parts Issues

Blog Article

Discover Undercarriage Parts for Heavy Machinery

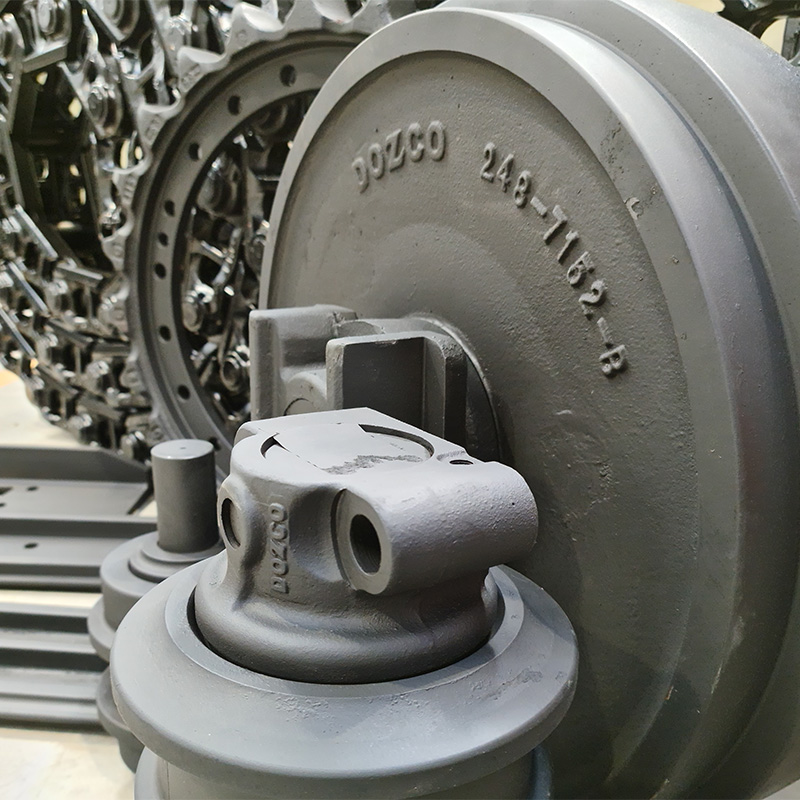

Recognizing the complexities of undercarriage components is necessary for the ideal performance and long life of hefty machinery. From track footwear to gears, idlers, and rollers, each element plays a crucial function in the performance of the equipment.

Relevance of Undercarriage Parts

The undercarriage parts of hefty machinery play a vital function in guaranteeing the total performance and longevity of the equipment. These elements, consisting of tracks, rollers, chains, idlers, and sprockets, create the foundation upon which the machine operates. A properly maintained undercarriage not only offers stability and assistance to the hefty equipment yet likewise adds substantially to its operational efficiency and performance.

One of the crucial benefits of buying top quality undercarriage components is the reduction of downtime and upkeep costs. By utilizing resilient parts that can stand up to the roughness of heavy-duty applications, drivers can lessen the demand for constant repair services and substitutes, thus taking full advantage of the maker's uptime and general life expectancy.

Additionally, appropriately working undercarriage parts ensure ideal weight maneuverability, grip, and circulation, allowing the heavy equipment to run smoothly even in tough terrains. This reliability is crucial for markets such as farming, building, and mining, where tools efficiency directly impacts project timelines and productivity. Finally, the relevance of undercarriage components can not be overstated in keeping the performance and long life of hefty equipment.

Kinds Of Track Shoes

When taking into consideration the numerous kinds of track shoes for heavy equipment, it is necessary to assess their layout and functionality in connection to certain functional requirements. Track shoes are critical components of the undercarriage system, providing stability, weight, and grip distribution for heavy equipment such as excavators, bulldozers, and spider cranes.

The most usual types of track footwear consist of:

** Grouser Shoes **: Including elevated metal bars (grousers) along the shoe's surface, these track shoes supply boosted traction in challenging terrains like mud, snow, and loosened gravel. undercarriage parts.

** Dual Grouser Shoes **: Comparable to grouser shoes however with an extra set of grousers, these track footwear provide also higher traction and stability, making them suitable for extremely harsh surfaces.

** Triple Grouser Shoes **: With three collections of grousers, these track footwear offer optimal grip and stability, making them suitable for the most requiring conditions.

Picking the right kind of track shoe is vital for maximizing the performance and long life of hefty equipment while making sure security and performance during procedures.

Function of Rollers and Idlers

Rollers and idlers play important duties in supporting and guiding the track shoes of heavy machinery during operation. By stopping excessive slack or tightness in the tracks, idlers contribute to the total stability and performance of the equipment.

In addition, idlers and rollers collaborate to keep the track footwear in placement, stopping them from sliding or thwarting off more throughout procedure. Effectively operating rollers and idlers are essential for ensuring the durability of the undercarriage system and taking full advantage of the equipment's performance. Regular upkeep and evaluation of these components are necessary to identify any type of signs of wear or damage early on, preventing pricey repair services and downtime in the future.

Function of Sprockets in Equipment

Upkeep Tips for Undercarriage Elements

Efficient maintenance of undercarriage components is vital for making sure the longevity and optimum performance of heavy equipment. Regular inspection of undercarriage parts such as track chains, rollers, idlers, sprockets, and track shoes is important to avoid unforeseen malfunctions and expensive fixings. One vital upkeep suggestion is to keep the undercarriage tidy from debris, mud, and various other contaminants that can accelerate wear and deterioration. It is likewise crucial to make certain appropriate track stress to avoid premature wear on components. Oiling the undercarriage components at advised periods assists to decrease rubbing and prolong the life-span of the parts. Keeping an eye on for any type of uncommon noises, resonances, or modifications in device efficiency can suggest potential concerns with pop over to these guys the undercarriage that require prompt interest. By following these maintenance suggestions carefully, heavy machinery drivers can reduce downtime, reduce operating prices, and optimize the productivity of their equipment.

Final Thought

To conclude, the undercarriage components of heavy machinery play an essential duty in making sure the smooth functioning and longevity of the devices. Comprehending the importance of track shoes, idlers, rollers, and sprockets, as well as carrying out appropriate upkeep practices, can considerably impact the total performance and performance of the machinery (undercarriage parts). Normal inspection and timely replacement of damaged components are important in taking full advantage of the life expectancy and efficiency of heavy machinery

Rollers and idlers play essential duties in sustaining and assisting the track footwear of hefty machinery during operation.In heavy equipment, gears offer an important function in transferring power from the engine to the tracks, allowing the equipment to relocate effectively and effectively. These components are connected to the axles or last drives of the machinery and work in conjunction with the tracks to move the devices onward or backwards. Regular inspection of undercarriage parts such as track chains, rollers, idlers, gears, and track shoes is essential to stop unexpected break downs and costly repairs. Understanding the relevance of track shoes, idlers, gears, and rollers, as well as applying correct maintenance methods, can substantially impact the total efficiency and effectiveness of the machinery.

Report this page